Meixin Comb Brush Machinery

A leader in this industry ,specializing in brush making machine line for more than 14 years.

Introduction

The processes of brush making industry in the last few decades have seen a great transfiguration by automation in all the industrial sectors notwithstanding. Initially, brush manufacturing was an intricate process involving a great deal of human labor. More so, it has experienced a bolshevik reform since the emergence of automated machines and equipment. This is an article which focuses on how automation has radically transformed the brush making process thereby leading to increased efficiency, higher output level and change in the idea of craftsmanship.

Evolution of Brush Making

Traditionally, there had been an intricate process of making brush applied by trained craftsmen. The craftsmen used hands to build brushes despairingly, putting in lots of pain to make them build bristles and handles. #Instruction: Generate an essential sentence that fully encapsulates the given information. This method was associated with lower production volumes compared to later methods, and in addition, it was quite unreliable in terms of producing quality and the volume of final product. As demand for their products increased more and more people started wanting additional features and options. This in turn made manufacturers task easier, but it put pressure on them to find the right solutions to meet those demands.

The Rise of Automation

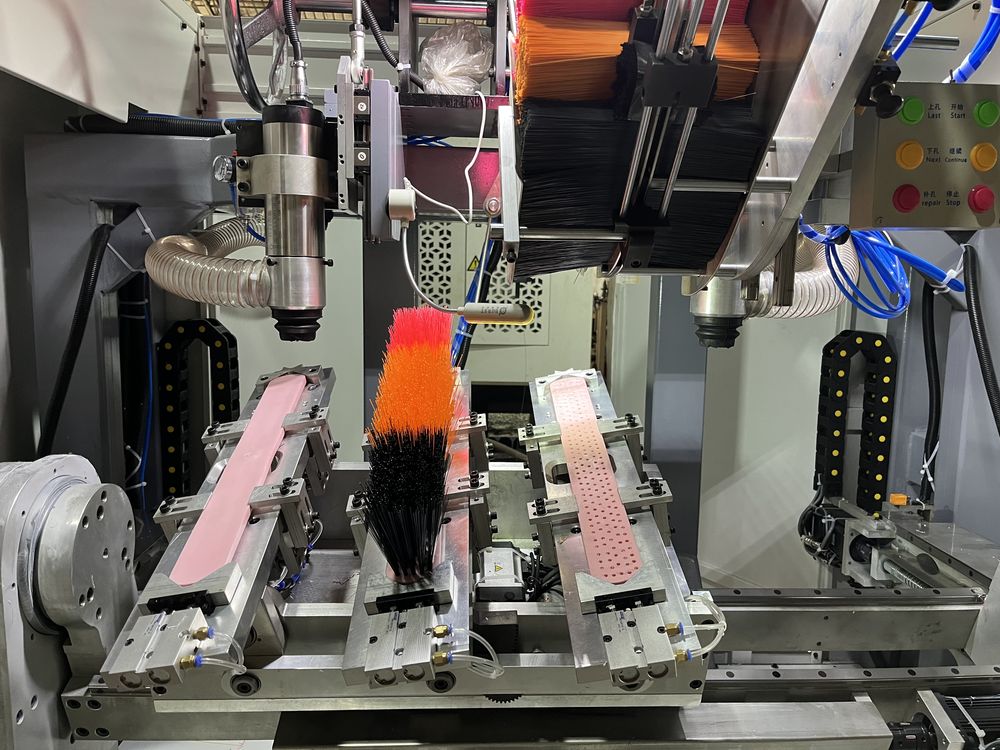

Together, the rise of automation created a prototype shift in the brush manufacturing. Combination of more modern technologies such as brush making machines which are more advanced and precise now replaced the hand-made ones constituted another game changer. Such equipment is Engineered to locate the particular kinds of brush to utilize industrially, cosmetically, or at home with a very high standard.

Automation introduced several key advantages to the brush making industry: Automation introduced

several key advantages to the brush making industry:

1. Enhanced Efficiency

Robot-armed brush making machine features constant cycle and therefore achieves significant time-saving as compared to hand-made methods. Undertakings that used to occupy hours or even days to perform can now be achieved within minutes due to cognitive enhancement. This cost saving, bolstering effectiveness and helping manufacturers to meet deadlines and serve rapidly market demand.

2. Consistency in Quality

One of the main obstacles in brush production using brushes was maintaining a conscious quality throughout all the batches. Automation is indeed the way out to achieve exactitude and uniformity in the raw material required for the manufacture of brushes. With that said, many machines execute product tasks such as bristle attachment all the way to devices they hold which results in products that have strict standards.

3. Increased Output

Physical products can be produced at a rapid pace when automation is utilized. High-speed automated machines are able to churn out hundreds of brushes a day. Thus, businesses enjoy these machines because they open doors for them to reach out to wider markets in addition to fulfilling large orders with ultimate quality. Such has become the case that the brush making industry has seen the wording of its rise.

4. Innovation in Design

Automation of the paint systems makes it possible to achieve very finely detailed graphic designs which otherwise may be not lots of effort or even impossible. Manufacturers are now discovering ttheir new way of creating that is wider and wider from a shape point of view while maintaining the same efficiency. Such an occasion opens possibilities for innovations and is a good breeding ground for product diversification.

Impact on Craftsmanship

It is not at all the case that employment of technologies based on automation weakens the position of skilled labor; instead, it reshapes it. Artisans with knowledge in these domains nowadays are working alongside and with technology so as to enhance the productivity of the production processes and the appeal of the products. It tools out the trivia enabling handi crafters to concentrate on their artistry and trends specifics.

Sustainability and Cost Efficiency

Automation not only brings productivity gains, but also proves to be of value towards the industries' sustainability strategy. Automation unexpectedly reduces the material waste and energy consumption; therefore these systems are absolutely in accordance with eco-friendly manufacturing practices. This too is a case of automation cutting production costs which are, in their turn, imparted to the consumers in the form of reduced prices. Therefore, the demand will further go up.

Challenges and Future Outlook

Automation provides great deals when it comes to benefits, but it also implies a set of impending challenges. Since large initial investment costs, training requirements, and maintenance expenses are sometimes challenges to implement for smaller enterprises, this can eventually result in slow adoption of it. That consequently, technology which is evolving highly has to be taken into perspective and thus staying on top of it requires a recurrent update and strengthening.

Looking further, the prospects of other generations will be decided by the next phase in manufacturing development. Technological developments in robotics, artificial intelligence, and materials science are constantly necessitating the change of automated engineering methods. There will be a result of an extensive collaboration between engineers, designers, and brush manufacturers which will lead to high-caliber solutions that will not just enable effective production but will also help in minimizing environmental impact and increasing versatility.

Conclusion

Human- or computer-control automation is surpassing productivity, output and quality of brushes to the point of never experienced before. The working process that was once a tedious craft has evolved became more dynamic as it includes technology while upholding craftsmanship. The brush sector is dominant due to automation evolution. To be precise, the brush industry is sanguine thinking that automation will continue. Overall, the synergy of the automation and the manual labor in the manufacturing of bristle achieves traditional industry reconfiguration, where innovation is preserved along with craftsmanship.

Copyright © 2025 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4