Meixin Comb Brush Machinery

A leader in this industry ,specializing in brush making machine line for more than 14 years.

Introduction to Brush Manufacturing and Sustainability

Brush manufacturing is a wide term that indicates making a lot of brushes to be used in various sectors in our daily life such as personal care, cleaning, maintenance, and automotive plus industrial. The sector has been constantly struggling with the issues of material waste, energy consumption, and environmental pollution which have become common characteristics of such an industry. Although the outcome of the evolution and green practices where the originally mentioned problems are crammed up have become a long way, a sustainable approach to manufacturing is now possible.

Evolution of Brush Manufacturing Machinery

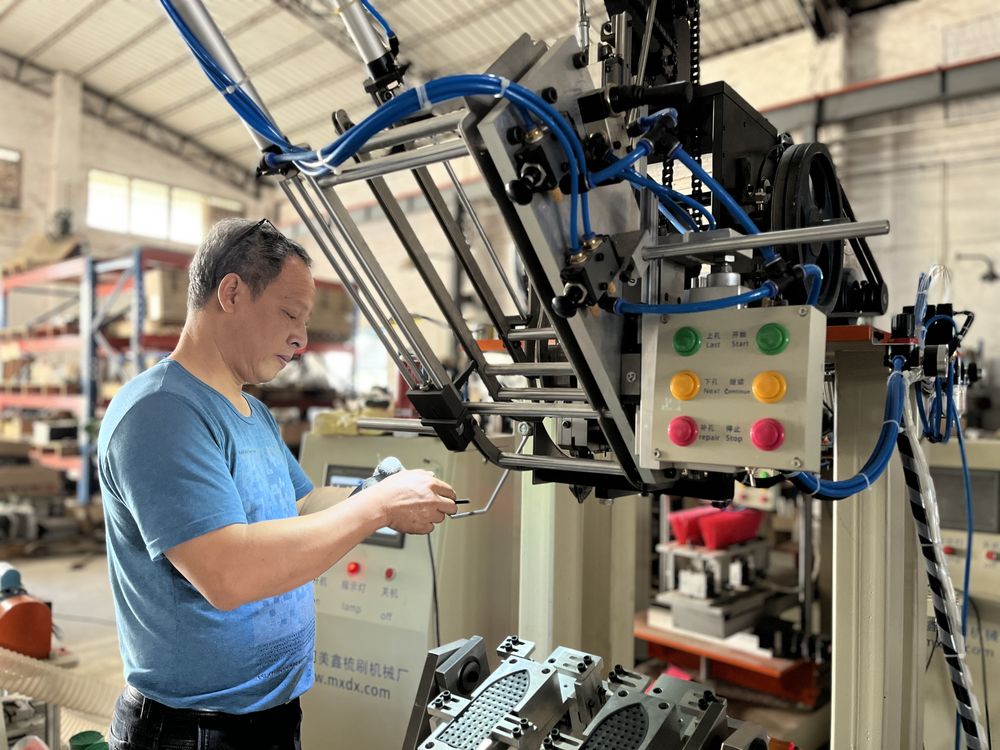

A green revolution has begun in brush making when the latest technologies aimed at achieving this objective can be developed so that the entire production processes become as efficient and resource conserving as they can. One instance is buying robots for brush-making, so they do not spend on manual and labor-consuming methods prior to the development of this system. In addition to increase in production, these machines also positively impact on reduction of from wastage since it is possible to accurately control on use of the material being processed.

Features of Sustainable Brush Production Machinery

Modern brush manufacturing machines are equipped with features specifically tailored to promote sustainability: Modern brush manufacturing machines are equipped with features specifically tailored to promote sustainability:

Material Efficiency: That is done by the set of the more advanced machines leaning at optimization of MA usage during the production process, preserving the waste at the minimum level. And, to achieve this goal, the adoption of waste-reducing technologies which enables precise cutting and molding is applied.

Energy Conservation: Sustainable machines are being engineered to perform energy-efficiently, using energy-saving methods for instance automatic shutdown systems and adjustable speed modes. This, thus, helps to lessen the operational cost and also to keeps the greenhouse gas emissions lower.

Recyclability: In addition to reducing the emission of greenhouse gases, recyclable materials are also progressively used for brush production by manufacturers. sustainable machines circumvent the use of pure plastic, metal, and natural fibers for brush heads but instead, employ recycled plastics, metals, and natural fibers so the products can fit the circular economy rules.

Water Management: Water use is an integral element of brush manufacturing in particular, and it’s important for cleanings and finishing of the product. Sustainable machines have water recycling systems incorporated, that are largely to the amount consumption and unwater- consumption.

Automation and Precision: The automated brush-making machines have not only perfected the craft of making brushes that previously no human could produce but also, the end product with fewer defects. As a result of this, the necessity of repeat work and further reduction in material waste is created.

Environmental Effects of Machine-Aided Brush Production are Automatic.

The integration of sustainable machinery in brush manufacturing yields several environmental benefits: The integration of sustainable machinery in brush manufacturing yields several environmental benefits:

Reduction of Waste: Through the use of improved and enhanced design and machines that are more efficient,the sustainable manufacturing part of industry is leading to minimize waste at every stage of production.

Lower Carbon Footprint: Energy-saving figures and compartmental recyclables have a culminating effect of building a lower carbon footprint that is in tandem with the universal strategy of combating global climate change.

Resource Conservation: Sustainable machines that sustain the environment do that by cutting down on the extraction and consumption of the raw material, thus minimizing pollution in the environment and the overall conservation.

Compliance with Regulations: Manufacturers who maintain procedural standards in line with sustainable policies have more favorable chances of getting a lease with the governments than those that do not.

Case Studies: Show Casing an Ecofriendly Toothbrush Production.

Several case studies highlight the successful implementation of sustainable practices in brush manufacturing: Several case studies highlight the successful implementation of sustainable practices in brush manufacturing:

Automated Precision Cutting Systems: Another manufacturer has rolled out automated cutting technologies that maximize material usage and they have saved at least 30% of the raw material wastes while improving the product quality.

Recycled Material Integration: One more company rolled out the plastic brush-making machines which can fully utilize recycled polymer, minimizing the use of the primal materials and avoiding the one-way economy.

Energy-Efficient Production Lines: Through replacing the brush manufacturer’s old production lines with energy efficient ones there were huge cost savings and very tangible emission reduction.

Future Trends and Challenges

In that regard, sustainable brush manufacturing evolution is shaped by further technical innovations and consumer demand changes. Key trends include:

• Smart Manufacturing: Incorporation of enabling technologies, such as IoT (Internet of Things) and AI (Artificial Intelligence) to advance production methods and resource utilization.

• Biodegradable Materials: Investigating into biodegradable and compostable materials used for brush components and preventing disposal to the environment at the end of their lifetime.

• Circular Economy Models: Tailoring down a circular economy model to allow for design and operation of a closed loop system for production and disposal of brushes.

Yet, challenges remain in place most notably the initial costs of upgrading to sustainable machinery and the fact that we have to use our skills and knowledge to constantly offer new ideas that are fit enough to satisfy different regulatory requirements and consumer expectations.

Conclusion

However, in the concluding part, the brush manufacturer's embrace of complex machinery is changing the environmental landscape sustainably. The manufacturers can increase their efficiency, reduce waste and become more environmentally responsible concurrently. They gain from the enhanced performance, and at the same time, they are helping to build a clean and sustainable future. As technologies continue to develop and as the knowledge about our environment becomes widespread, sustainable brush manufacturing will play an essential part in the way manufacturers adopt green thinking that is going to be on the cutting edge today and tomorrow. The investment in innovation, together with a strong desire to establish the equilibrium between the economics and nature, the brush manufacturers are showing the possible realm of the sustainable and sustainable future.

Copyright © 2025 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4