Meixin Comb Brush Machinery

A leader in this industry ,specializing in brush making machine line for more than 14 years.

1) Introduction:

Brush trimming machines are essential to many industries, but they are especially important in the industrial, electronics, and automotive sectors where the quality of the final product depends on the accurate trimming of brush bristles. These devices are designed to precisely trim and shape brush bristles, guaranteeing consistency and performance. This article explores the complex workings of brush trimming machines that allow for precise trimming, including their parts, guiding principles, and innovations that improve their accuracy.

Brush trimming machines are more than just mechanical tools; they are the pinnacle of precision engineering, made to exacting specifications for sectors where accuracy and consistency are critical. This section will go more deeply into the workings of these devices, examining the fundamental ideas that allow them to provide precise trimming as well as the advances

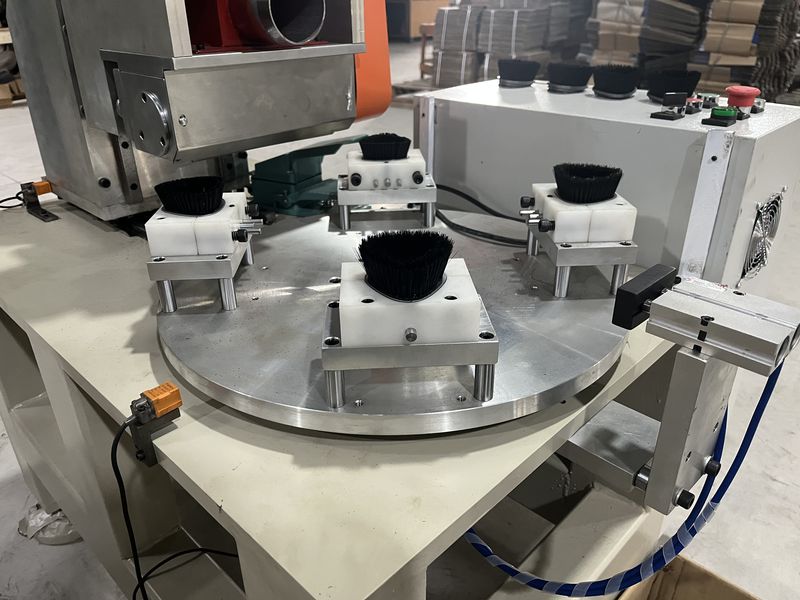

2) Fundamental Brush Trimming Machine Components:

To fully appreciate the precision of brush trimming machines, it is essential to first identify their basic components:

A. Preliminary Mechanism: The cutting mechanism, which usually comprises of oscillating cutters, linear blades, or rotary blades, is the brains behind a brush trimming machine. The material and needed precision determine which cutting mechanism is best.

B. Systems of Sensations: In order to guarantee that the trimming is done with the utmost precision, sensors are installed to monitor the operation, spotting variations in bristle length or brush alignment.

C. Control Unit: The depth, speed, and angle of cutting can all be adjusted with the customizable settings found on modern brush trimming machines. These controls can be precisely and repeatedly adjusted since they are frequently automated via a computer interface.

D. System of Holding and Feeding: This mechanism holds the brush firmly in place while trimming, moving it in a controlled way to expose various areas of the brush to the cutter. To guarantee consistent trimming, the feeding mechanism must operate with precision.

3) Mechanisms for control in Precision trimming:

Brush trimming machines use a combination of advanced mechanics and technology to achieve precision.

I. Methods of Reducing Vibration: Reducing vibrations during cutting is essential to achieving high precision. Smoother cuts are produced by the vibration dampening technology found in many machines, which stabilize the cutting process.

II. High-Precision and controlling movement: High-precision motors that regulate the feeding system and cutting blade movement are a feature of brush trimming machines. Even at fast speeds, these motors guarantee accuracy in every action.

III. Variations Control Systems: More sophisticated brush trimming machines might include adaptive control systems with dynamic cutting parameter adjustments depending on input received in real time. This guarantees that the machine can continue to perform precise trimming even in the event of variances in brush material or dimensions.

4) Sustaining and Extended Life Considerations:

Maintaining the accuracy of precision trimming machines over time is crucial, as they are substantial expenditures. The machine's longevity and reliable operation depend heavily on routine maintenance and appropriate treatment.

A. Tool Upkeep: To keep them efficient, cutting tools—blades or oscillating cutters—need to be replaced or sharpened on a regular basis. Ineffective tools can result in low-quality cuts, higher strain on the machine, and more frequent maintenance requirements.

B. Adjustment: To ensure accuracy, the machine's control systems and sensors must be calibrated on a regular basis. Small variations in sensor readings over time might add up and cause a loss of accuracy. Accurate feedback from the machine's sensors and control units is ensured by routine calibration.

C. Lubrication and Cooling Systems: To lessen wear and friction, the machine's moving parts—particularly the cutting mechanism—need to be lubricated on a regular basis. Certain machines have automated lubricating systems installed to guarantee smooth operation. Additionally, cooling systems are necessary to avoid overheating during extended operation, which might deteriorate the precision of the machine.

5) Advancements in Accurate Trimming Technology:

Brush trimming machines are constantly evolving as a result of technological advancements, adding new features that improve their accuracy and productivity. The development of 3D printing technology has allowed for the production of cutting tools that are specifically created to fit certain brush designs. These instruments can be tailored to the precise measurements and composition of the bristles, leading to increased accuracy and decreased wastage.

Brush trimming machines are becoming more and more integrated into smart manufacturing systems in the context of industry. Real-time monitoring, predictive maintenance, and the capacity to swiftly modify production procedures in response to shifting demands are all made possible by these technologies. Increased adaptability, decreased downtime, and consistently high-quality output are the outcomes.

Conclusion:

Brush trimming machines are intricate machinery made to withstand the rigorous requirements of contemporary production. These machines can meet the high requirements needed in a variety of industries thanks to a combination of sophisticated mechanical systems, accurate control technology, and creative solutions. The precision and capability of brush trimming machines are probably going to get much better as technology develops, providing even more efficiency and accuracy in the future. Anyone involved in the operation, maintenance, or design of these equipment must have a thorough understanding of their mechanisms in order to ensure that they are utilized to their greatest capacity.

Copyright © 2025 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4