special features:

1.With the 1 drilling and 1 tufting heads.MX207 its designed for the industrial disc brush for the road and others industrial used. The length of disc brushes are available to make according to customers requirement.

2.It can be drilling ,tufting at the same time.

3.you can tuft the machine with bristle,PP,PET,others.

4. Independent 3 axis motion ,simple, stable.

6. Perfect design, wont be miss the holes and get high productivity.

A/ brand of motor in the machine

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of drilling and tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. drilling and tufting excessive pressure alarm.

8. production speed is adjustable.

WD-4-TM3-B

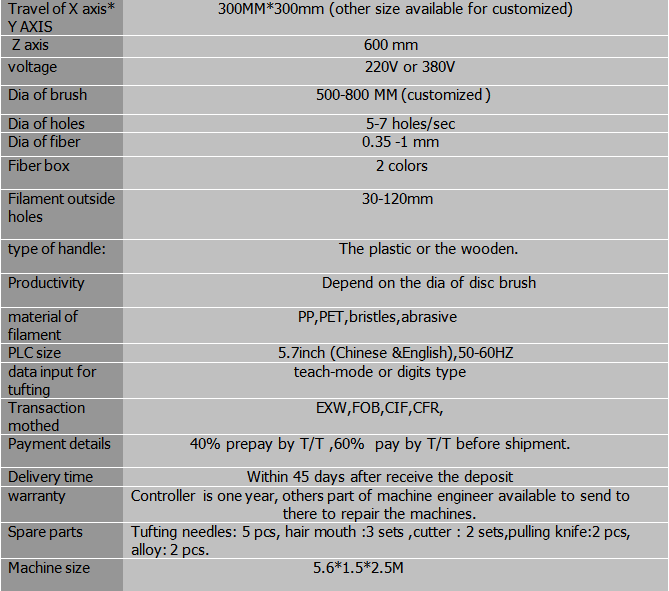

Item | Description | Unit | Parameter |

1 | Max Speed | Holes/min | 750-800 |

2 | Maximum brush holes | Holes/Piece | ≤100,000 |

3 | Hole Diameter | mm | 1.5-2.8 |

4 | Spindle quantity | Piece | 2+2 |

5 | Journey X axis | mm | 48 |

Jouney Y axis | 25 | ||

6 | Maximum program quantity | Piece | 2000 |

7 | Air pressure | Mpa | 0.6-0.8 |

8 | Power voltage, frequence | V,HZ | 220,50 |

Machine Power | KW | 3 | |

9 | Contour size(LxWxH) | mm | 1700x1250x1500 |

10 | Weight | KG | 1248 |

yangzhou kaiyue is a manufacture founded in 2005,

Welcome to visit our factory in China .Or check the video regarding our factory on website .

Sample is available .

yes they are popular in your market

FAQ:

1.Q:Are you a factory or trading company?

A:We are a factory

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Yangzhou City, Jiangsu Province, China, about 2 hours train from Shanghai .

All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:What is the material of your products?

A:The material is solid iron aluminum plastic

plastice can also choose material as customers’ requirement.

4.Q:How can I get some samples?

A: We are honored to offer you samples.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. KAIYUE people always attach great importance to quality controlling from the very beginning to the very end.

Could u tell me how to make a beautiful cabinets or doors?

A.Engraving working piece by CNC router

B.Trimming the working piece by sandpaper(Other tools u can use)

C.Sparying the professional PVC glue for better pasting, then drying it naturally

D.Putting small wooden block under working piece, for better pasting on the door(cabinets side ,&edge)

E.Putting PVC film on working piece and close it tightly with no air going inside, tnen starting the machine with heating time and temperature and the air pump absorbing time settled in advance( Changing according to different condition)

F.When finished heating and absorbing , working table moving out .cutting the rest PVC ,then trimming what you want)

We also have cnc router, vacuum membrane press machine ,If need it,Pls contact me

Copyright © 2025 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4