Meixin Comb Brush Machinery

A leader in this industry ,specializing in brush making machine line for more than 14 years

Introduction:

Today's manufacturing world is a concept where speed and accuracy are essential, through automated systems it is very possible. The brush making industry is to mention one sector where the automation technology has taken great steps. Using the latest machine technology and robotics is the way manufacturers can now make brushes faster, more precise and more uniformed in their performance. In this article, we delve into different aspects of automation technology and how it has changed the way brush are being made, in terms of increased efficiency and better output.

Evolution of Brush Making Machinery:

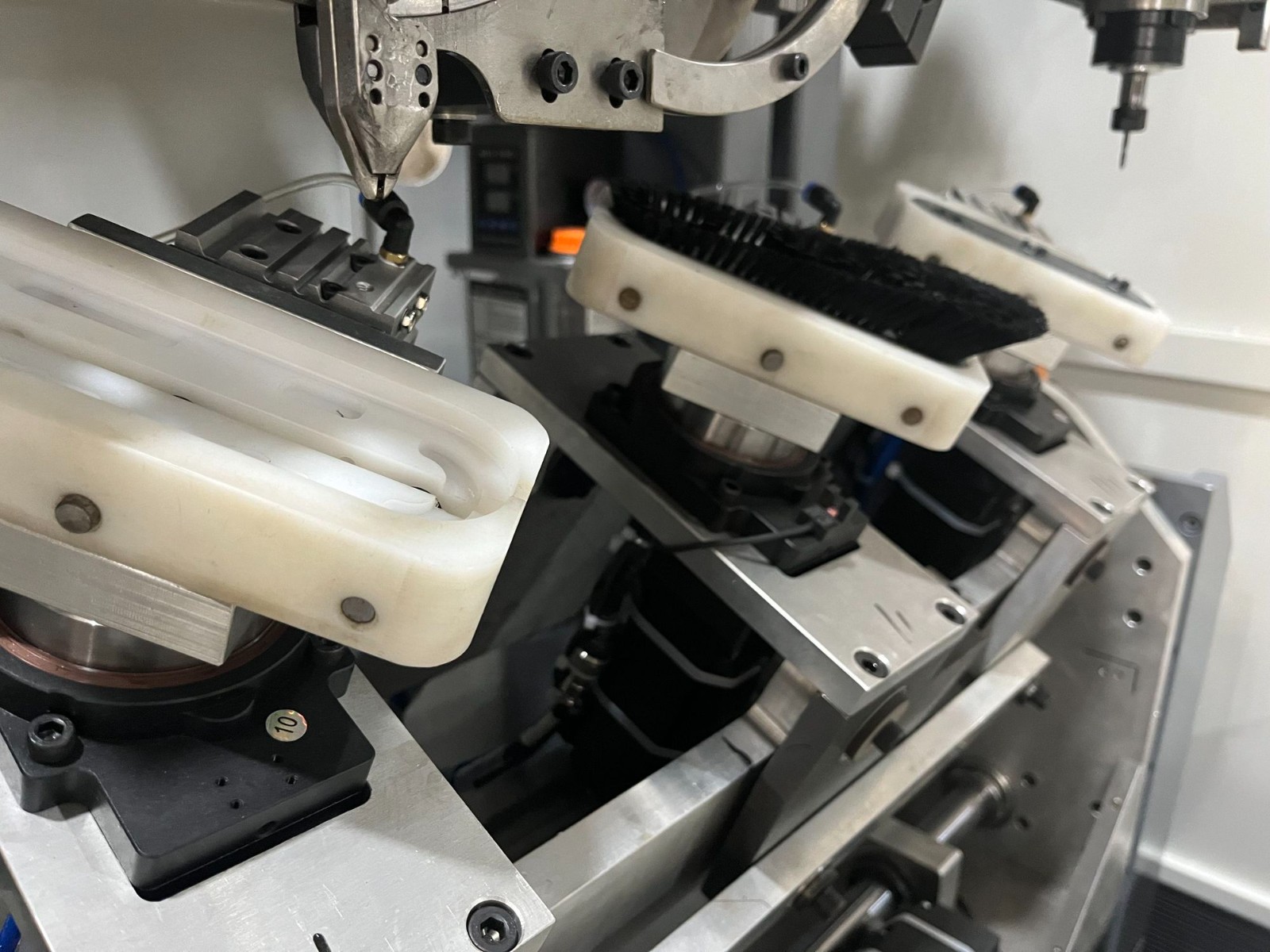

The mold for brush-making machinery may be traced back to the Industrial Revolution where the starting point of mechanical manufacturing was shifting through mechanization. The use of simple machines had a great impact on the productivity of brush making, but it was only with the emergence of advanced automobile machines that the whole idea of brushmaking machine was realized. Modern brush making machines, nowadays, has become very versatile and uses completely automated set of systems from bristle inserting to handle molding that makes the production process faster, eliminate or minimalize human errors, and thus improve overall productivity.

Key Features and Functions:

In the case of classic brush making machines, you will find the whole plenty of features providing unique efficiency for each procedure. Generally, they invite materials working with nylon, natural fibers, and wire, meeting the peculiar wants and preferences of the various industrial sectors. Additionally, they enable adjustment of parameters including brush length, loading, and pattern, thus productivity and quality from batch to batch.

Automated brush-making machine has one hallmark, its ability to be diverse. Low rebuild requires, these machines are capable to manufacture different type brushes, where wide range of work like painting, to gum cleaning is carried out by them. Nowadays, there is no need to produce volumes because manufacturers can freely shift from one production line to another, and production can be altered according to changing consumer demands.

Impact on Manufacturing Efficiency and Output:

The replacement of the Makino brush making equipment with automated machinery has been a substantial factor in the rise of manufacturing efficiency and production. Such machines, for instance, can work without interruption, for 24 hours a day or in a non-supervisory manner, so they substantially increase the manufacturers' productive capacity. Through shorter cycle times and less idle periods, manufacturers are in a position where they can deliver a large amount of an order in significantly less time than they usually to need to create things using the traditional methods.

Nevertheless, advanced automation has furnished the industry with a chance to perfect the processes of production for higher efficiency. Companies are increasingly able to automate repetitive tasks through the application of technologies and the application of new approaches. This results in faster elimination of production bottlenecks and more effective operation of production lines. Along with decreasing labor expenses, it offers higher productivity which is a major contributor to the overall prosperity of the enterprise. Next, automation has brought a great deal of progress in regard to product quality and consistency as well. Autonomous machines can achieve strict performance level via the full process control that oversees the manufacture of each hairbrush. One characteristic of the completed product is the uniform bristle distribution which can achieve the level of accuracy and precision only by automatic machinery.

Future Outlook:

Going further, intelligent machines wielding automation technology for brush making increases in efficiency and productivity is what future holds. Producers are working on creative solutions to boost machines functionality, using wide variety of options like artificial intelligence, predictive maintenance, and environment friendly production. Managers by means of AI algorithms are able to optimize schedules, predict failures of the equipment and identify possible improvements of the process, and so on. Not only that it increases the speed and efficiency of the production process but also creates an advantage of a rapid reaction to corresponding market requirements.

Automation, along with predictive maintenance, is part of the technological improvements that are happening. Manufacturing companies can observe the actual performance of equipment in real-time with aid of data obtained from sensors embedded inside the machines that help them predict and prevent occurrences of potential problems that might arise. The prevention system contributes minimal downtime and maximum lifespan of the machinery, by means of which 100% performance is kept alive in long-term perspective.

Conclusion:

Subsequently, automation has brought about a revolution in the brush-making by making it possible to achieve this through high output, thereby invoking less labor, and at the same time, of course, this expedites the production process. With the ability to take advantage of cutting- edge machines and robotics infrastructure, manufacturing can not only streamline production processes but also improve workflow effectiveness and guarantee the application of accurate standards throughout. Technology development leads to presen-ving even more promising future. Continuous innovations are involved in this progress which will change the level of efficiency, quality and sustainability.

Copyright © 2025 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4