Meixin Comb Brush Machinery

A leader in this industry ,specializing in brush making machine line for more than 14 years.

Introduction:

Manufacturing industry is one of a kind place where innovation becomes the means to bring about huge leap in terms of efficiency, productivity and quality. Worth mentioning, automated brushes production was one of the cutting-edge technologies of those years. Machines have revolutionized the brush production process on a large scale so that manufacturers can now get shaved off time without compromising on accuracy and efficiency. Brush making machines not only change the look of the manufacturing sector, even more, they improve the quality, production capacity and work conditions of the sector.

Evolution of Brush Making Machines:

By far, back in days, brush making was rather an artisan job where artisans with numerous hours of experience were making each brush by hand with their sheer skills. This method was not only a time-consuming process but it did not allow proportional production which could have posed threat to metropolitan populations. Although manual tools like brush making machines made their debut in the industry, the landscape of this industry radically changed.

The cutting edge of the first machine engraving designs dates back to the later part of the 19th century when the era of the Industrial Revolution was in full swing. They (machines) mechanized the whole system of weaving the bristles and molding the handle entirely and fastening the labor of human beings. In the course of time, technologies improved and these eventually gave rise to machines of a higher grade which rival anything in efficiency while making different brushes possible.

Key Features and Functions:

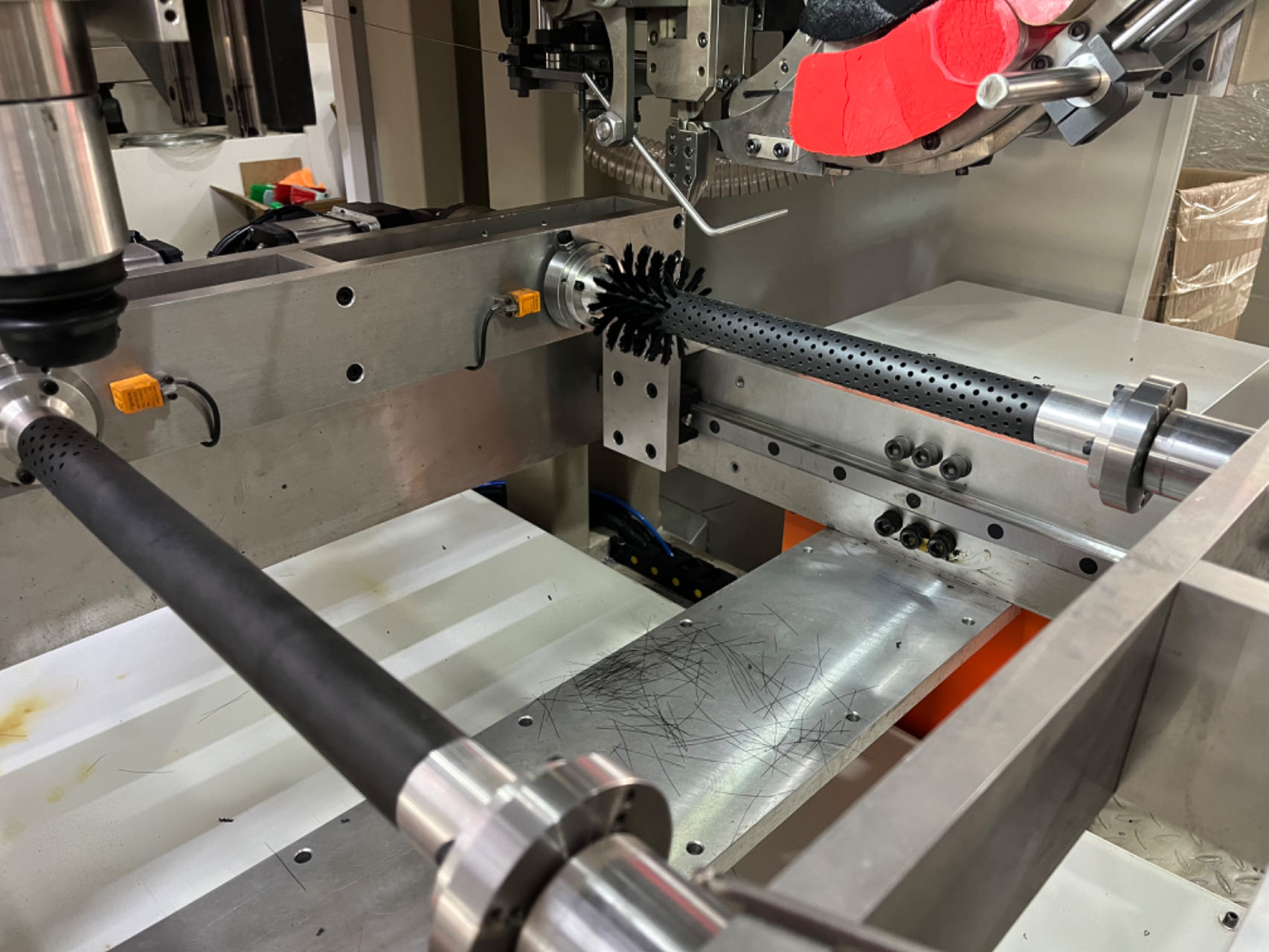

The production machine of today surpasses the design of conventional brush making machines by almost all renowned companies with its wide array of features that are tailored to enhance the performance of all the manufacturing activities. Such as these machines, can be able to work with different materials such as nylon, natural fibers and the wire this goes well with most of the industry helping it in increasing creative designs for different entities. Moreover they give the machine the power of parameters precision, such as bristle length density and the design, which gives the product the uniformity and quality. The capacity to diversify and assign goods for different designs is one of the major characteristics of brush making machines. As a result, they can be used for smoothly functioning as different brush types according to the need such as paint brushes, tooth brushes, cleaning brushes, and industrial brushes with minor adjustments. This versatility not only increases production flexibility, but is able to as well enable manufactures to meet the challenges of a fluctuating markets.

Impact on Manufacturing:

The establishment of brush making machines has caused a total merge of the whole manufacture industry engines. It began with the first and foremost, automation has substantially boosted the factory productivity and output capacity. It comes as no surprise that with machine process that runs for the whole time with minimal supervision, manufacturers are able to mass produce much greater orders in the context of traditional production. Moreover, machines for making brushes have granted the ownership of quality custom made brushes to both low- and high-income individuals. Before this period, handcrafted brushes expensive on a prohibitive way and consequently they were accessible only to a particular group of artisans. Yet, the lower cost due to mass production that has been achieved by brush making machines enables brushes to be affordable even by consumer from differing socio-economic standing.

Future Outlook:

With technology climbing to higher levels daily, it is evident that brush machines engineering time has not run out. The manufacturers will be competing with one another by the amount of innovative and investing they will be doing in research and development to raise the capabilities of machines further. This will make emphasis on areas like artificial intelligence, predictive maintenance, and sustainable production techniques. Besides, IoT-based technology is an integrated part of real-time machine performance monitoring that assists in proactive maintenance and minimal downtime in line production. In addition, the research in materials science is intending to get quite a big stack of brush materials which allow manufacturers to be a bit more creative and to pick what they really want.

Conclusion:

At last, rotary broom machines with sheer efficacy, precision, and multifunctionality has taken the production at hand to a completely new level. In this case what was once a humble beginning with the machines dating back to the 19th century has developed to the current advanced technology that have influenced the type of brushes being made, consumed and perceived. The area of brush making machines innovation lays out in front of us in the future - a place where we will be driven by sociotechnical systems powered by advanced AI, predictive maintenance, sustainability, and materials science. These machines being capable of providing a perfect scale brush with a high level of consistency will still stay in demand and thus, continue to be helpful to different industries, shaping efficiency, technology, and the economy.

Copyright © 2025 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4