Company Advantages1. The manufacturing process of MEIXIN steel

brush machine covers sophisticated workmanship. Its mechanical parts and components have to go through rough machining, cutting, grinding, honing, finish milling, and polishing. If something wrong with the machine, Meixin engineers are available to provide service overseas

2. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY possesses strong local resource advantages. Meixin imported TBI precision ball screw and straight line guide rail, servo motor, Italy brake motor

3. steel brush machine perfects the performance of brush tufting machine during its actual use. Meixin innovative ability enables to constantly develop new products

4. Taking steel brush machine into full consideration during the design, brush tufting machine are all produced with the highest quality. The quality of the products also has been strictly controlled by Meixin

5. Being qualified with steel brush machine makes brush tufting machine consequent to be the fashion trend. Ease of installation is one of the most characteristics of Meixin products

special features:

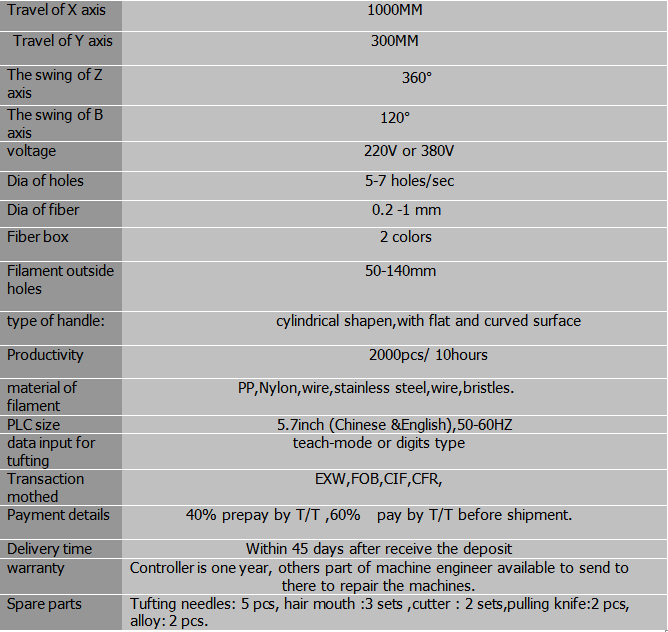

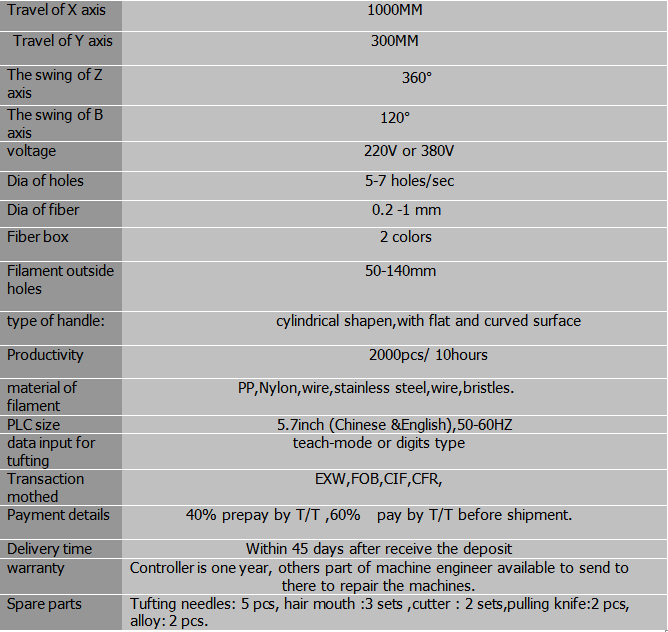

1. With one tufting heads,independent 4 axis motion ,it used for the any shape pf brooms. Like flat brooms and other shape of brooms. It suitable for any wooden or plastic brush handles tufting.

2. The filament outside hole can be 50-140mm.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

3.This machine with the new design of tufting.easy operate.

B/ brand of motor in the machine.

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

C/Controller features:

1. its provided with manual data input as well as teach in data input method. With the 5.7 touch display, it can work with the Chinese or English.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. In a global economic environment, we ship our products across China and to other countries, including America, Australia, Japan, and South Africa.

2. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY will continue to create profits for customers. Get an offer!