Company Advantages1. The manufacturing process of MX machinery carbon brush making machine includes several stages. The product will go through mold fabricating, injection molding, stamping, surface treating, and assembling. All our products are made by highly advanced technology

2. After years of improvement, the product has received more and more attention at home and abroad and has great commercial value. Meixin innovative ability enables to constantly develop new products

3. disc

brush machine has the peculiarities of carbon brush making machine , which is used in toilet brush making machine . Ease of installation is one of the most characteristics of Meixin products

special features:

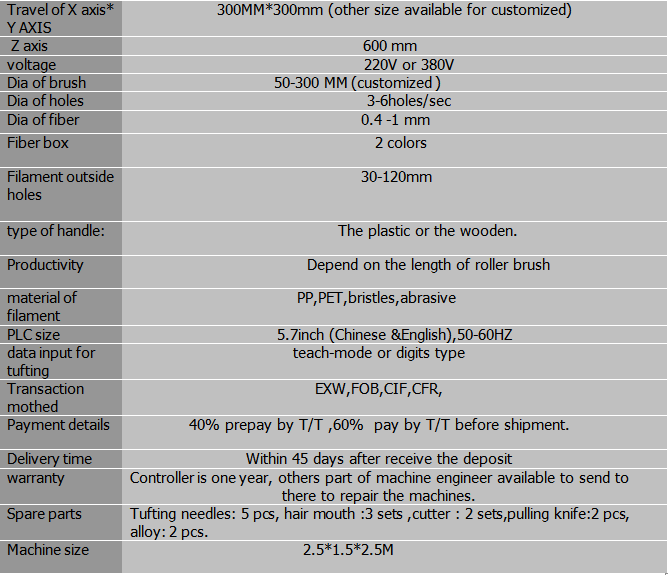

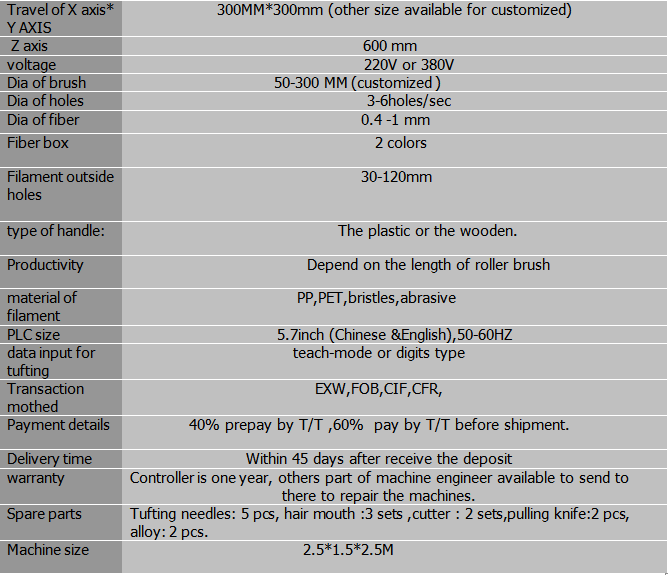

1.With the 1 drilling and 1 tufting heads.MXR201 its designed for the industrial roller brush for the road and others industrial used. The length of roller brushes are available to make according to customers requirement.

2.IT DESIGNER FOR small holes 3mm-6mm. can be drilling ,tufting at the same time.

3.you can tuft the machine with abrasive,PP,PET, bristle,others.

4. Independent 3 axis motion ,simple, stable.

6. Perfect design, wont be miss the holes and get high productivity.

A/ brand of motor in the machine

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of drilling and tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. drilling and tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is a well-known Chinese company. We have proved ourselves to customers with superior design and manufacturing capability by delivering carbon brush making machine . We have a well-trained customer service team. They are equipped with professional communicative skills and profound product knowledge, which enables them to provide full support services to all our product end-users and business partners, including pre-sale training and after-sale support services.

2. We work with every material and finishing process in the industry, giving us unrivaled versatility when it comes to designing the perfect product for customer needs.

3. Our company has a dedicated product development team. They can discover the exact needs of customers while balancing engineering and manufacturing constraints to provide innovative solutions. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY provides professional service for every customer. Inquire online!