US $3-30 / Pieces | 200 Piece/Pieces (Min. Order)

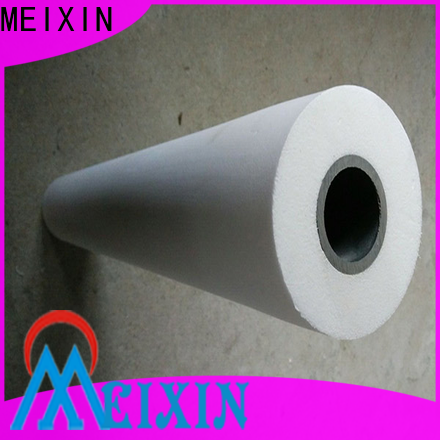

Brush Material: PU, PVA, PO

Core Material: Metal, Plastic, PVC, etc

Application: Glass Cleaning, Water suction

Color: White

Size: Custom Size

Type: Sponge Roller

Certification: SGS, CE, ISO, etc

MOQ: 200pcs

Sample: Available

Supply Ability: 10000 Piece/Pieces per Month

Copyright © 2023 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4