special features:

1. With one tufting heads,independent 4 axis motion ,it used for the any shape pf brooms. Like flat brooms and other shape of brooms. It suitable for any wooden or plastic brush handles tufting.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

3.This machine with the new design of tufting.easy operate.3 colors.

4. With the 5.7 touch display, it can work with the Chinese or English.

A/ brand of motor in the machine

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

5 Axis CNC Brush Drilling And Filling Machine

5 Axis CNC Brush Drilling And Filling Machine

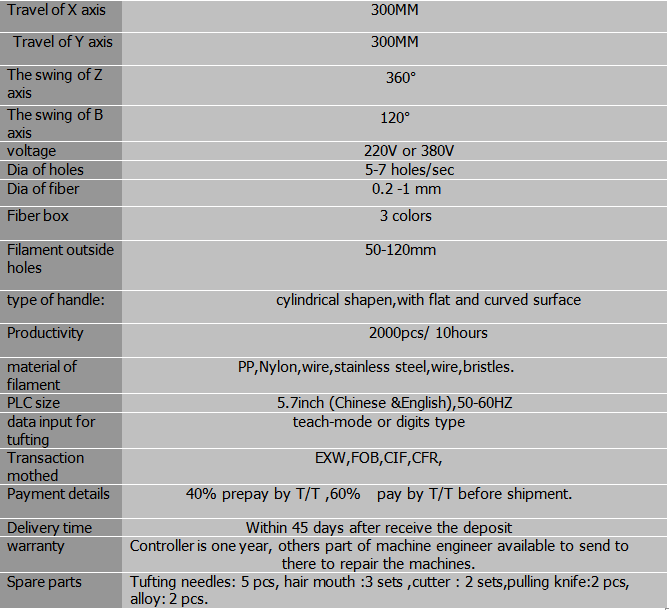

Specification:

This machine used for drilling and flocking brush sheet(wood or plastic).Place the brush wire into box, steel wire putted onto feeding dish. Continuous putting into brush jig and automatic clamping. The machine finished drilling and flocking process.

Application Range:

1 | Adopted brush sheet material | Plastic, wood |

2 | Adopted brush making types | Flat brush, dish brush, toilet brush.etc |

3 | Adopted flocking materials | Nylon and plastic wire, animal and plant wire |

4 | Filament diameter | 0.1-0.6MM |

5 | Filament length | 40~320mm |

6 | Apply wool nozzle diameter | 2.8,3.0,3.5,4.0,5.0,5.5,6.0mm |

7 | Apply flocking hole diameter | 2.5~6.0mm |

Parameter:

1 | Normal tufting efficiency | 600-1000 holes/min |

4 | X axis stroke | 650mm |

5 | Y axis stroke | 600mm |

6 | Z axis stroke | 300mm |

7 | U axis stroke | 180° |

8 | V axis stroke | 180° |

9 | Main motor power | 3KW |

10 | Total power | 6KW |

11 | Machine size | 3.8M * 1.8M * 2.1M |

12 | Machine weight | 3.5 Tons |

Working Enviroment:

1 | Power | Three phase five wires, 380V, 50Hz |

2 | Install Area | Indoor: flat floor, clean, dustless, no acid-base |

3 | Temperature | -5-40ºC |

4 | Altitude | below 1000M |

5 Axis CNC Brush Drilling And Filling Machine

5 Axis CNC Brush Drilling And Filling Machine

Copyright © 2025 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4