special features:

1. With one tufting heads,independent 4 axis motion ,it used for small round toilet brush, others. It suitable for any plastic brush handles tufting.

2. The filament outside hole can be 30-50mm.

3.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

4.This machine with the new design of tufting.easy operate.

5. Please note that The productivity is 2400-2600 pcs/10 hours.

2AXIS High speed brush tufting machine

Features :

1) It's used to tuft flat plastic brooms, the maximum tufting speed is 6.3 holes per second. Please note that the plastic broom blocks must be molded with holes in advance. It can also tuft other flat brushes, as long as operator changes grippers accordingly.

2) With 5.4'' touchable screen, the interface is available in various languages, such as Chinese, English, Spain, Russian, etc, as required by clients.

3) With PLC(Programmable Logic Controller), which operates precisely with excellent stability.

4) The working table of this broom machine is composed of straight-line guide rails and screw mandrels with high precision, which is quite stable and durable.

5) Two grippers are installed on worktable, which work alternatively and continually. Thus there's no need to stop to change brush blocks, which increases productivity.

6) Operator enters data for tufting positions under "Teach Mode". On operation interface, operator could insert, delete, adjust, copy, divide and move holes, which is quite simple and convenient.

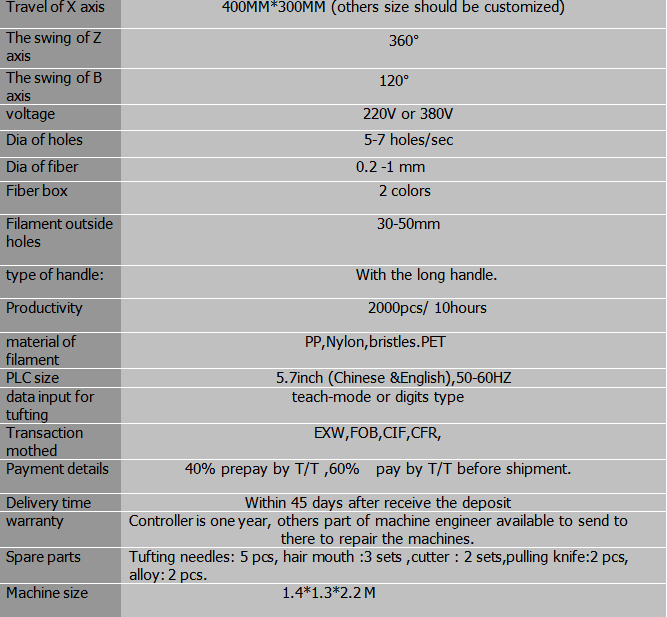

Technical Parameter for 2-Axis High-Speed Brush Tufting Machine 2A-01:

Standard Working Area of 2-Axis | X-axis x Y-axis = 400mm x 200mm |

Material of Brush Handle | Plastic, wood |

Material of Brush Filaments | PP, PVC, PET, nylon |

Length of Filaments (Outside Holes) | 10mm - 120mm |

Diameter of Brush Filaments | 0.08mm - 1.2mm |

Diameter of Holes | 3mm - 6mm |

Colors of Filaments | Either single color or two colors |

Maximum Tufting Speed | 6-7 holes per second(depend on sample) |

Specifications of Machine Body | 1.20m(L) x 0.90m(W) x 1.68m(H) |

Motor (Power System) | With servo motors by default |

Data Input for Tufting Positions | Teaching-type: Operator manually puts tufting head into each hole, one by one, the position of these holes will be saved by computer one by one. By this way, all data for tufting position has been entered and saved. Digits-type: Operator manually enters digits(coordinates of X/Y axis) for tufting position. |

Touchable Screen | With 5.4'' touchable monitor controller; interface is in English or other language required by client, operating in dialogue-mode, which is quite simple and easy. |

Speed Adjusting | Frequency-conversion stepless-adjustable speed |

Qty of Programs Saved | It saves totally 80 programs for different broom models |

Gross Weight | Around 650KGS(with Controller box) |

Programming | PLC (Programmable Logic Controller) |

Power Supply | 1-phase 220V or 3-phase 380V, 50-60Hz, 600W |

Replaceable Grippers | Operator could make other flat brush models, as long as he changes grippers accordingly. |

Tufting Mode | Anchor-type (using flat wires) |

Packing | It'll be packed into wooden cases. |

Steel Wire Brush Paint Roller Handle Making Machine is to produce paint roller handle frame expertly.It can not only make lips stamping but also threading and end chamfering fully automatically.Plastic cover dressing device can be manual type or combined in line in automatic type for options and pin making machine is also available upon request.

Model | GT-PR-8RS |

| Wire size | 3.0-8.0mm |

| Feeding length | 0-700mm |

| Production capacity | 10-12pcs per minute |

| Motor power | 7.5KW |

| Dimensions | 1970*1150*1990 |

| Weight | 1400kg |

Copyright © 2023 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4