special features:

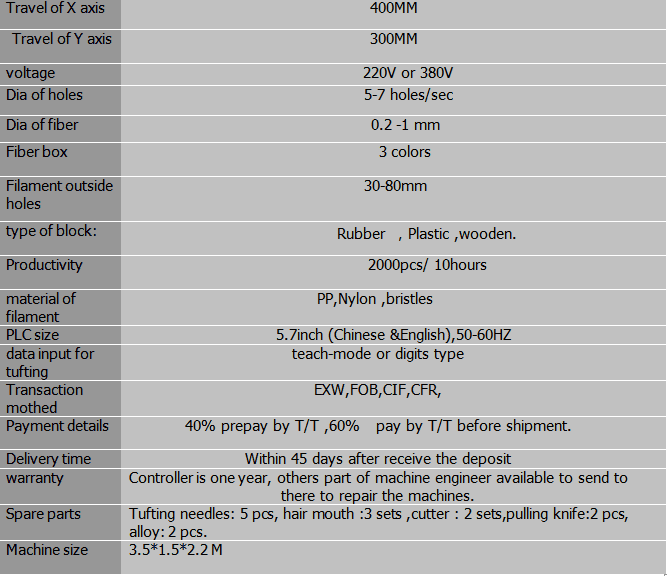

1. This machine with one tufting heads, independent 2 axis motion, only for tufting. Please be sure that the plastic head or block have been drilled.

2. The speed is 5-7 holes/sec .

3. FMX fixture allows fast change over for a new brush tufted production.

3.This machine is used to product the snow brushes.

4. About the touch display, it has teo lauguafe syatem, Chinese and English .

5. you can tuft in the machine with the PP,PET,others

brand of motor in the machine

1.Delta inverter, Panasonic servo motor .

2.Taiwan TBI ball screw guide way and Taiwan HIWIN .

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Plastic PET broom/rope/brush monofilament extrusion machine/production line:

Features:

1. Using the recycling PET bottle flakes

2. Multi-purpose machine of filament for broom, rope, nets, etc.

3. Same transparency as virgin polyester slices, the tensile strength and shock resistance are stronger

4. Low energy consumption, high production capability

5. Easy operate, saves manpower

Specification of Plastic PET monofilament extrusion machine:

Model | GTLS-70 | GTLS-80 | GTLS-90 | GTLS-100 |

Screw L/D | 30:1 | 30:1 | 30:1 | 30:1 |

Gearbox model | 200 | 225 | 225 | 250 |

Main motor | 18.5kw | 22/30kw | 30/37kw | 45kw |

Capacity(kg/h) | 80-100kg | 100-120kg | 120-140kg | 140-160kg |

Mould Dia. | 200 | 200 | 200 | 200 |

Filament Dia. | 0.1-2.5mm | 0.15-2.5mm | 0.15-2.5mm | 0.2-2.5mm |

Details of Plastic PET monofilament extrusion machine:

Machine | Qty. | Specification |

PET flakes drying machine | 1set | Capacity: 200kg

|

Automatic Loader and hopper | 1set | Loader: Model: ZJ-800 Loading type: Screw Loading Loading Capacity: 800g/h Loading power: 1.5kw,

Stainless steel Hopper: Capacity: 400kg

|

SJ80/33 Single Screw Extruder | 1set | Main motor Motor: AC37KW, Inverter Controlling

|

Spinning die | 1set | Material : Made by quality mould steel |

Water Cooling Tank | 1set | made of stainless steel Tank length: 1000mm

|

Five-roller stretch unit | 1set | Speed: 0.5-120m/min Driving motor: 5.5 kw, AC inverter control

|

Hot water tank | 1set | Tank length: 4000mm Heating power: 18KW Temperature: 100 ℃

|

Seven-roller stretch unit | 1set |

Speed: 0.5-120m/min Driving motor: 7.5 kw, AC inverter control

|

Oiling unit | 1set |

AC inveter control speed

|

Pneumatic tension Unit | 1set | Pneumatic system 1set

|

Winding machine | 1set | Double working station Torque motor: 5N.m Square frame size: 128x50mm Automatic length counter

|

Electric Control Cabinet | 1set | AC motors: SIEMENS

AC Inverter: ABB Temperature Controller: OMRON, Japan Relay: OMRON, Japan AC Contactor: SIEMENS

Over current protective of motor Over pressure protective of screw.

|

Application of Plastic PET monofilament:

Plastic PET broom

Plastic PET rope:

CS-G8802L

Copyright © 2025 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4