A/ brand of motor in the machine.

1.Delta inverter, panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of drilling and tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of,delete or copy.

6. Normal working or positioning testing.

7. drilling and tufting excessive pressure alarm.

8. production speed is adjustable.

C/special features:

1. FMX fixture allows fast change over for a new brush tufted production. This machine with 3 grippers.

2. Independent 5aix motion,suitable for any wooden or plastic brush handles tufting.

CE certificated wood broom brush making machine/wood drilling tufting machine

Technical characteristics:

1, Equipped with two drilling heads and one tufting head;

2, Equipped with two high speed drilling heads: hole diameter from Φ3.0mm up toΦ6.0mm, and tufting tools from min.Φ3.0mm up to Φ6.0mm;

3, Hair by: round nails or flat nails;

4, three types of platform can be chosen as follows:

Platform for radial, parallel and radial/parallel tufted brushes

Platform for bowl brushes and semi-spherical brushes

Platform for rollers and hair brushes

5, PLC and Touch Panel Control System, displays in either Chinese or English;

6, Allow saving as 2000 procedure and easy for the creation of new models;

7, our machine can produce either one color or two color brush, and also drilling or tufting separately.

8, setting of worktable: high-precision straight-line rail and ball screw, steady and durable.

9, Material of Brush Handle: Poly styrene, return materials, wood

10, Material of filaments: PP, PET, PVC, and STEEL WIRE

11, Application: To make varieties of toilet brush and radial brushes

12, High Speed Motor: Delta High-Speed Motor

13, AC motor: Delta Brake Motor

14, Type & Brand of Drive/Motor: Delta servo motor by default, can adopt some brand motor & driver requested by users.

15, Adjust Speed: Frequency-conversion stepless-adjustable speed

16, Replaceable Fixture: FMS type. It can be easily changed to make other kinds of brushes.

17, Head mode: Anchor or Staple

18, Program System: CNC system, high precision, stability and efficiency

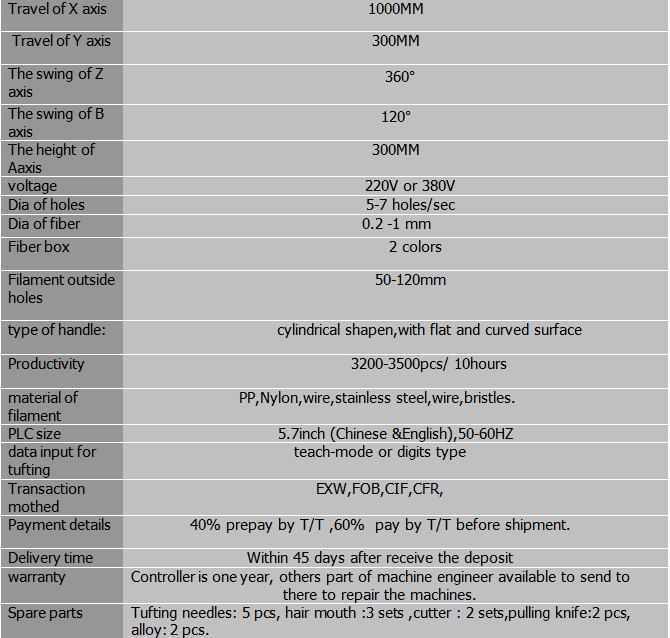

Technical parameters

Maximum production speed | 450 holes/minute |

The maximum filament length | 240mm |

Dia. Of tufting holes | Φ3.0mm-φ6.0mm |

Machine size | 2.5m*1.4m*1.98m (L*W*H) |

Power consumption | 3000W |

Driving motor | AC Servo Motor |

Power Supply | Three-phase 380V |

Weight(gross weight) | 2.5 Ton |

This set of machine is a professional yarn drawing line, which is mainly used for producing PP, HDPE net yarn, and also can be used for processing other plastic yarns via corresponding adjustment.

This line consists of extruder, cool water tank, the first stretching device, hot water tank, the second stretching device and coiling machine. The matching devices for production process are complete, so it can continuously finish the whole procedures from putting material to coil yarn onto bobbins...

Copyright © 2025 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved 粤I CP备18042005号-4