Company Advantages1. MEIXIN carbon brush making machine is manufactured with precision. Its manufacturing process includes conventional machining, special processing, and heat treatment. Meixin innovative ability enables to constantly develop new products

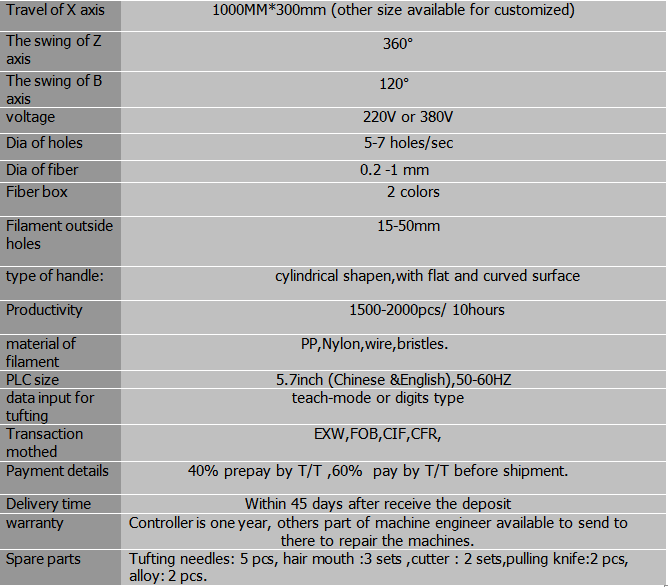

2. The product has significant development advantages compared to other product. Meixin uses stable motor and metal box to reduce noise

3. The product features an easy operation. It has a relatively simple operating system combining a powerful processing flow and provides simple operation instruction. Meixin supplies high-quality

brush machine4. The product has the advantage of stable mechanical properties. Having been treated under extremely cold temperatures, its mechanical components are tensile enough to withstand extreme industrial conditions. If something wrong with the machine, Meixin engineers are available to provide service overseas

special features:

1. With the 2 drilling and 1 tufting heads, MXF192 its used to produce the any shape of hair brushes. There with the photo attached.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 3 grippers.

3. Independent 4 axis motion ,suitable for any wooden or plastic brush handles tufting.

4. Its use the small machine to produce ,only catch one pcs nylon in one holes.

5. Perfect design, wont be miss the holes and get high productivity.

6. Its suitable for the customer who start to manufacture the hair brush ,not only ess cost but also good return.

A/ brand of motor in the machine

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of drilling and tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. drilling and tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. MEIXIN is a credible enterprise that focuses on manufacturing Drilling And Tufting Machine . Our company has a multi-skilled workforce. The workers move with the workload instead of waiting for the work to come to them. This allows us to always focus on the needs of customers rather than the capabilities of the worker, which improves production quality.

2. The factory has implemented a comprehensive production management control system. This system covers pre-production inspection (PPI), initial production check (IPC), and during production inspection (DUPRO). The implementation of this system has offered a strong guarantee for production efficiency and product quality.

3. We are supported by an executive team. They can ensure that our staff has sufficient competent resources and information for the implementation and delivery of the business plan. To adapt to market's needs, JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY will insist on long-term improvement for broom manufacturing machine. Check it!