Company Advantages1. MX machinery brush tufting machine is developed under the concept of high-tech. During the R&D stage, its mechanical parts, microelectronic device, and intelligence control device are considered by the technicians. The products must be 100% tested to ensure their functionality, reliability, security and durability before shipment

2. By following the strict standards, MX machinery controls every step to ensure the quality of brush tufting machine. If something wrong with the machine, Meixin engineers are available to provide service overseas

3. The product has high performance reliability and relatively long service life. Meixin innovative ability enables to constantly develop new products

4. Due to our strict quality control system, the quality of our products is guaranteed. Meixin keeps strict quality control of the products

special features:

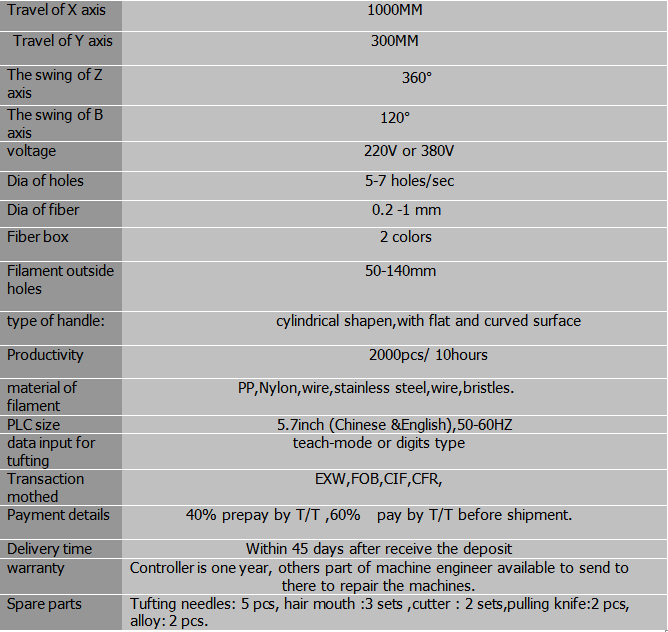

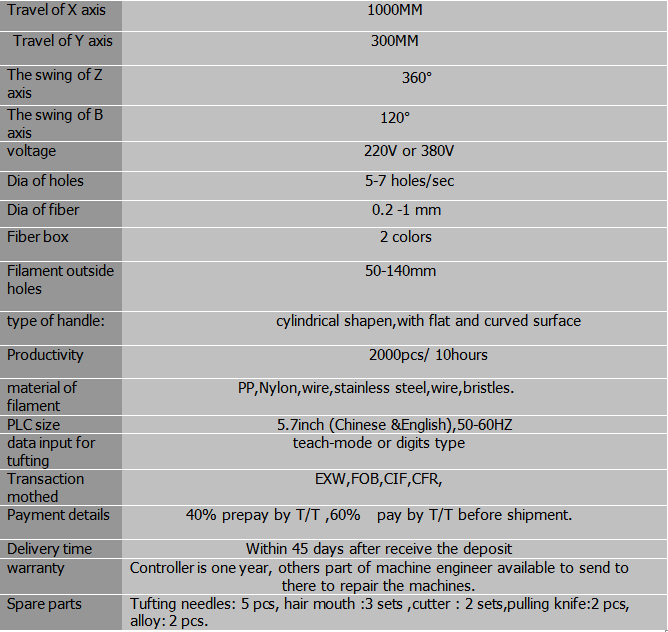

1. With one tufting heads,independent 4 axis motion ,it used for the any shape pf brooms. Like flat brooms and other shape of brooms. It suitable for any wooden or plastic brush handles tufting.

2. The filament outside hole can be 50-140mm.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

3.This machine with the new design of tufting.easy operate.

B/ brand of motor in the machine.

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

C/Controller features:

1. its provided with manual data input as well as teach in data input method. With the 5.7 touch display, it can work with the Chinese or English.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is a China-based firm that is influential and reputable in the manufacturing industry of brush tufting machine. Strict tests have been conducted for Brush Making Machine .

2. We have a top R&D team to keep improving quality and design for our brush tufting machine.

3. Our production capacity occupies steadily in the forefront of the brush tufting machine industry. We gear towards more sustainable business and environment development. We make efforts in introducing effectual sewage disposal and exhaust emission clean systems to minimize the adverse impact on our environment.